Award Winning Sprayer Operation - get the tips

Paul Gater, First Assistant at Caldy Golf Club, near Birkenhead, has been recognised as one of the UK’s top sprayer operators. International turf journalist, Laurence Gale, visited Paul on the course, to pick up some of his Top Tips and learn from his experience.

After 14 years at Caldy, on the north-west Wirral peninsular, near Liverpool, Paul Gater was promoted to First Assistant in 2008, taking on more responsibilities that would specifically involve taking on all the duties regarding the use of chemical products and fertilisers.

He is now effectively responsible for all the spraying operations around the course, keeping accurate records and overseeing the purchase, storage, application and disposal of any relevant chemical products.

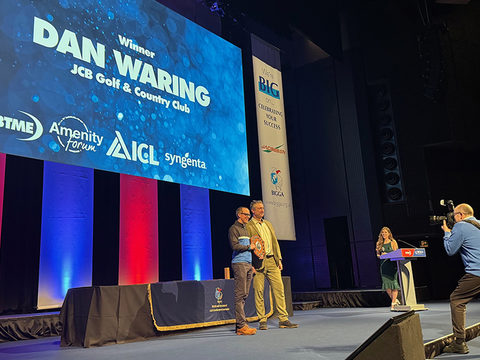

Holding a National Certificate in Greenkeeping, along with PA 1, 2, and 6 spraying qualifications, it was Paul’s dedication to this area of work that encouraged his being put forward for the Amenity Forum Sprayer Operator of the Year (AFSOOY) awards.

Like most golf courses, Paul sees his role of the spray technician being an important cog in the running and upkeep of the golf course.

The role is very multi-tasking, not only responsible for the upkeep, running and cleaning of the spray equipment, he also requires knowledge of the weed, pest and diseases he is trying to control - while at the same time developing the best strategy and timing of when to apply the appropriate control and feed products.

|

Making a detailed plan of the course can identify areas for special care when spraying, such as watercourses, for all operators |

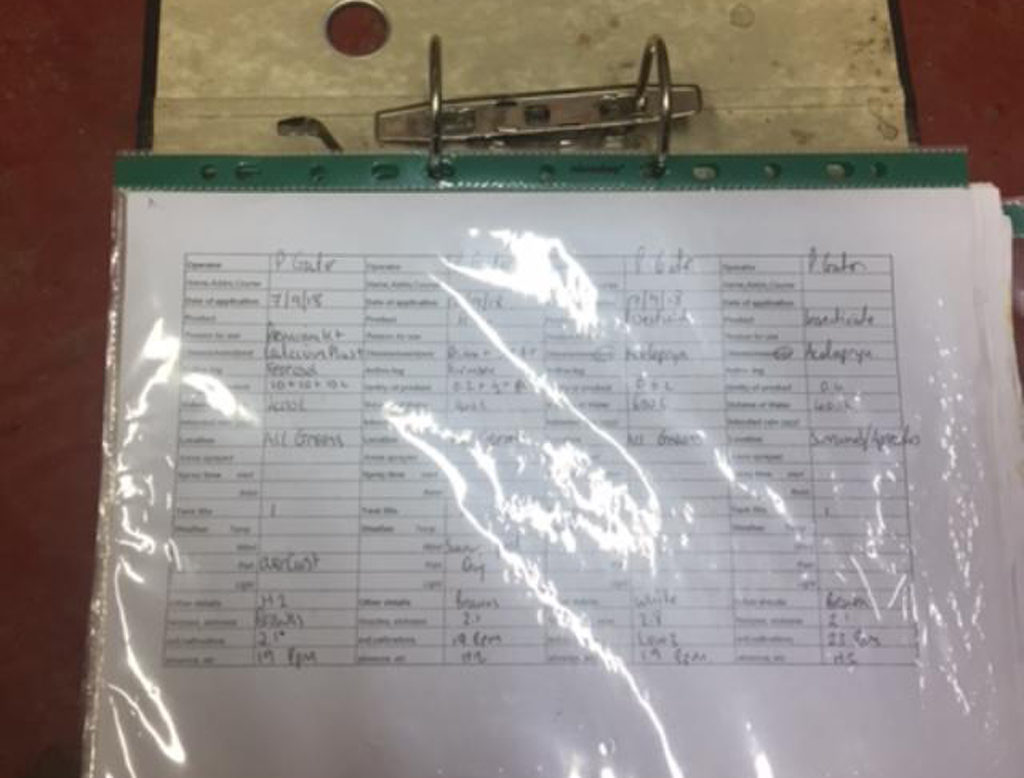

Paul advocates record keeping as one of the most valuable aspects of his job. The very fact you have accurate spraying records enabled him and Carl Crocher, his course manger, have a better understanding of what’s happening out on the course.

|

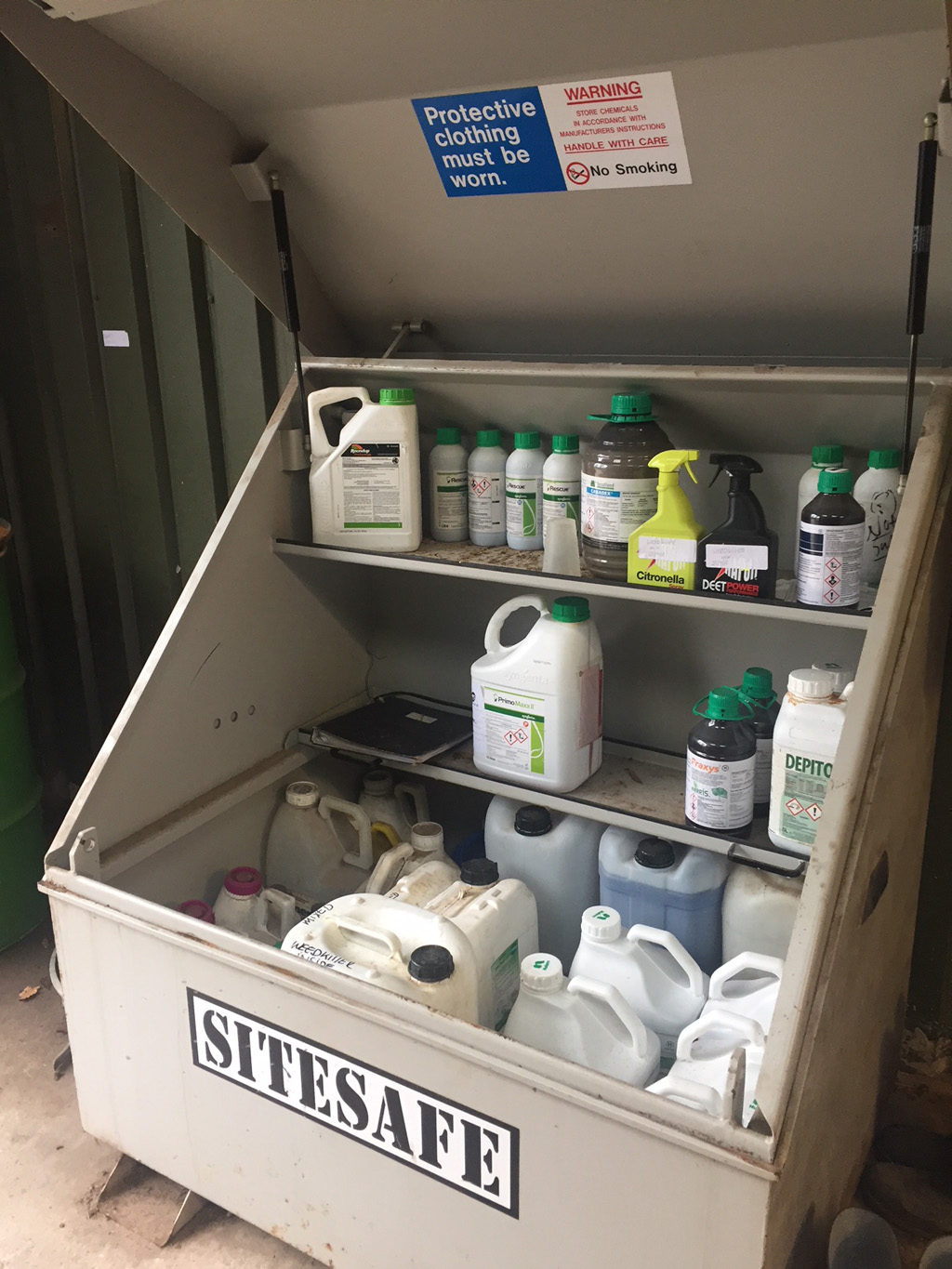

Chemicals should be securely stored when not in use |

This data provides much valuable information for both Carl and Paul to make informed decisions on the future maintenance requirements out on the course. It’s important to keep records for traceability, for insurance schemes and for information for emergency services, he adds.

|

Shrouded booms can mitigate drift on windy sites. Low drift nozzles are another alternative |

The club have invested in a new 600-litre tank sprayer and a 50-litre pedestrian walk over machine. During the winter months, Paul tends to use the pedestrian sprayer in and around the greens areas to reduce the problem of compaction.

|

Pedestrian sprayers still need to be calibrated, serviced and maintained for good accuracy |

Like most golf clubs they all have their own unique set of problems and challenges when it comes to weed, pest and disease control. Paul and Carl are always keen to use several Integrated Pest Management strategies.

Keeping the grass plant healthy is key, generally achieved with good greenkeeping practices that encompasses good mowing, feeding and aeration regimes, coupled with a scarification and top dressing programme, where applicable and dependant on budgets.

|

Efficient store management, with clear labelling, is an important part of the operator’s role |

|

Assessing and recording results helps with future decision making, with Paul reviewing Rescue applications |

They also tank mix appropriate products, ensuring they read and comply with product labels and recommendations. During any one year the sort of products they have been using at Caldy GC include: Primo Maxx; Dew smart; compost tea; soluble irons; sulphate ammonia; Porthcawl; wetting agents and Rescue.

|

Keep PPE separate and know where the first aid kit is – preferably on the sprayer |

|

Maintain clear, up to date records |

Paul was runner-up in the category for sports turf application with a mounted sprayer. Look out for more tips from previous winners, including Nathan Hume of S H Goss.

Paul’s Top Tips for accurate spraying, which made him a winner :- |

|

|

|

|

|

|

|

|

|

|

|

|