Soil application on target

Targeting soil applications can be a particular challenge for sprayer operators, but is crucial to getting best performance from any treatment.

With soil target sprays, the aim is to minimise initial contact and retention on the leaf. As soon as a spray starts to dry on the leaf surface it begins to bind to leaf wax layers – which can be within minutes of application, particularly at lower water volumes. That is highly beneficial for foliar acting fungicides, for example, but potentially detrimental for products targeted at the soil.

Large droplets, with greater velocity and momentum when they leave the nozzle tip, are far more effective at bouncing and rolling off the leaf.

Using a higher water volume will help in getting the spray down through the sward to the soil surface and not sticking to the leaf. However, in most instances further irrigation after application has been shown to enhance movement of the product into the soil profile.

An application at 800 l/ha still only equates to 0.08 mm of water, compared to the Acelepryn recommendation of three to six mm of irrigation as soon as possible after treatment, for example; that is is the equivalent to a water volume of 30,000 – 60,000 l/ha. |

Spraying at lower water volume, with smaller droplets retained by the leaf, and then seeking to wash off with irrigation, reduces the chances of success. Treatment at higher water volumes gets the product to an area where irrigation water has a better chance of moving it towards the target.

A recent survey into the application practices in the UK with Acelepryn has highlighted that up to a third of applications were made with too little water volume. The label stipulates 600 l/ha to aid movement through the sward; with target areas so critical on a product like this water volume should not be compromised. |

For soil targeted treatments, application in light rainfall or when the leaf surface is already wet, can prove effective; especially if irrigation resources are limited.

|

|

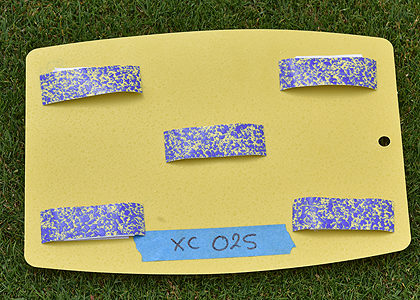

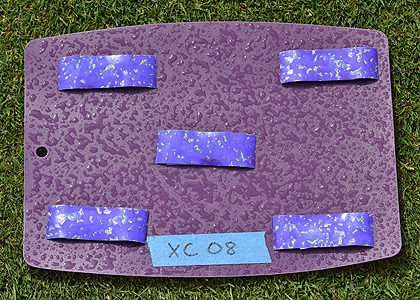

Water sensitive paper test demonstrate how the water volume and droplet velocity of the 08 XC Nozzle (right) over wets the leaf and gives rapid run down to the crown and soil surface, where it can be more easily washed into the soil, compared to the 025 XC Nozzle operated at the same pressure and speed but where the droplets are captured and held on the leaf surface. | |

Nozzle selection

To deliver higher water volumes, it is far better to change to a larger nozzle size and to slow down, compared to increasing the pressure on a smaller nozzle (Table 1). The effect of increasing pressure would be to create more of the smaller droplets that are less effective at penetrating down to the soil and, in a worse scenario, highly susceptible to drift.

08 flat fan | 04 flat fan | |

Output per ha | 600 l/ha | 600 l/ha |

Sprayer speed | 4 km/hr | 4 km/hr |

Operating pressure | 1.2 bar | 5 bar |

Number of sub-100 micron drift susceptible droplets per ml of spray | 550 | 67,000 |

Table 1. Increasing pressure to deliver higher water volume from a smaller nozzle hugely increases the proportion of small droplets less effective at reaching the soil and more susceptible to drift | ||

When using sprayers with auto-rate controllers take care that, as you speed up, the operating pressure will quickly ramp up to maintain consistent flow rates. The potential effect on droplet sizes, and the proportion of low-penetration drifty droplets from flat fan nozzles could be highly significant. Faster speed will also increase turbulence and drift potential, which further exacerbates the issues of higher pressure and small droplets.

Cutting drift

Reducing drift is essential to get the maximum amount of product where it is intended to work. Stewardship is improved and risks to non-target areas are reduced. New nozzle technology can reduce drift by 50%; 70% or even 90%, compared to flat fans operated in the same conditions.

Furthermore, managing drift can significantly improve the consistency of spray pattern across the boom, especially if there is any gusty wind movements.

Weather record monitoring during Syngenta application trials has shown that even in a ‘perfect’ spray conditions, with an average wind speed of 1.4 m per second, actual wind speeds varied from 0.8 to 4.6 m per second – with up to 20% reduction in performance of soil target sprays with flat fans, compared to 90% drift reduction nozzles. |

For turf applications the Syngenta XC Nozzle has offered a step change in drift reduction, compared to flat fan nozzles. The picture below shows the drifty fine droplets of flat fans on the left of the boom, compared to XC Nozzles on the right operated at the same pressure and speed.

The XC design also enables effective operation and spray pattern at lower pressure, to further reduce risk of drift (Table 2). They also produce a more consistent pattern if the boom height moves from the optimum 50 cm, on undulating ground or driving up onto greens, for example.

Available in 025; 05 and 08 sizes, the XC design produces a far more consistent droplet spectrum. For soil target applications, the 08 nozle can deliver optimum water volume at practical operating speed and pressure.

New Syngenta research is looking at the potential of 90% drift reduction technology specifically for applications to turf surfaces.

Operating pressure | 2 | 3 | 3 |

Sprayer speed | 6 km/hr | 6 km/hr | 4 km/hr |

Output per ha | 520 l/ha | 640 l/ha | 960 l/ha |

Droplet number per ml of spray | 10,294 | 15,717 | 15,717 |

Droplets per m2 | 535,288 | 1,005,888 | 1,508,832 |

Table 2. Syngenta XC Nozzle 08 output | |||

When targeting the rootzone the best practice is to maintain optimal levels of organic matter and maintain an effective wetting agent prgramme, independently of any application. If there is no wetting agent programme in place and soil profiles are difficult to penetrate due to compaction, hydrophobic conditions or high levels of thatch, then inclusion of Qualibra in tank mix with a soil target fungicide or insecticide would help.

For most soil target applications, best practice would suggest: |

|

|

|

|

|

The sprayer operators’ role is vital to balance all these factors to optimise results. The XC Nozzle technology and application techniques are available to precisely hit target spray zones and minimise the risk of spray drift, whilst still delivering consistent results.

A new look Art of Application Zone on the GreenCast website now provides easy access to a range of tools and advice to aid accurate spraying.

Use the GreenCast Turf App to find the optimum nozzle choice, operating speed and pressure for each application. | |

Download from the App Store of Google Play. Click below for links: | |